Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

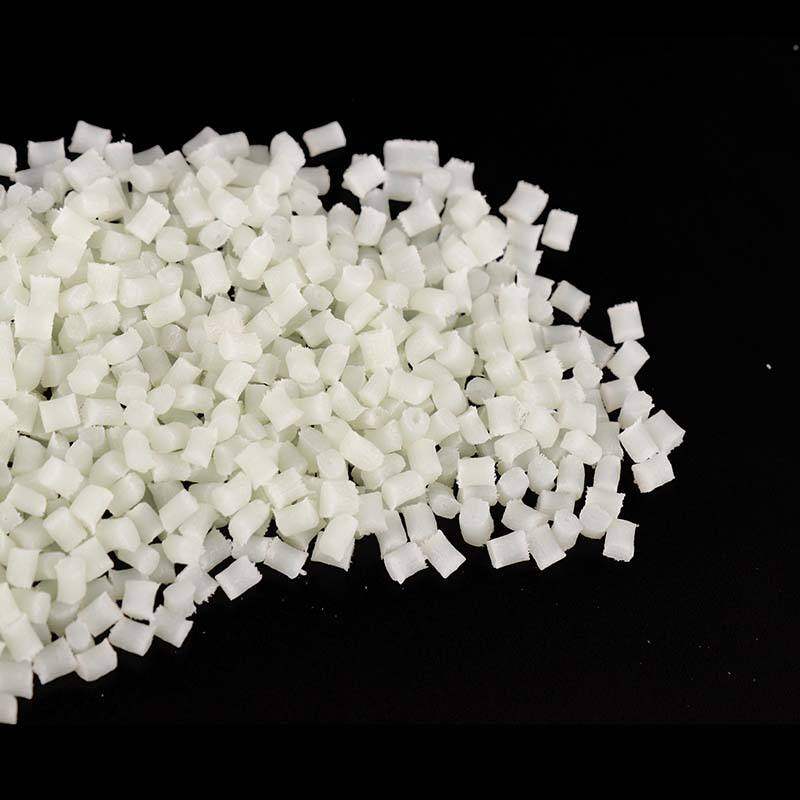

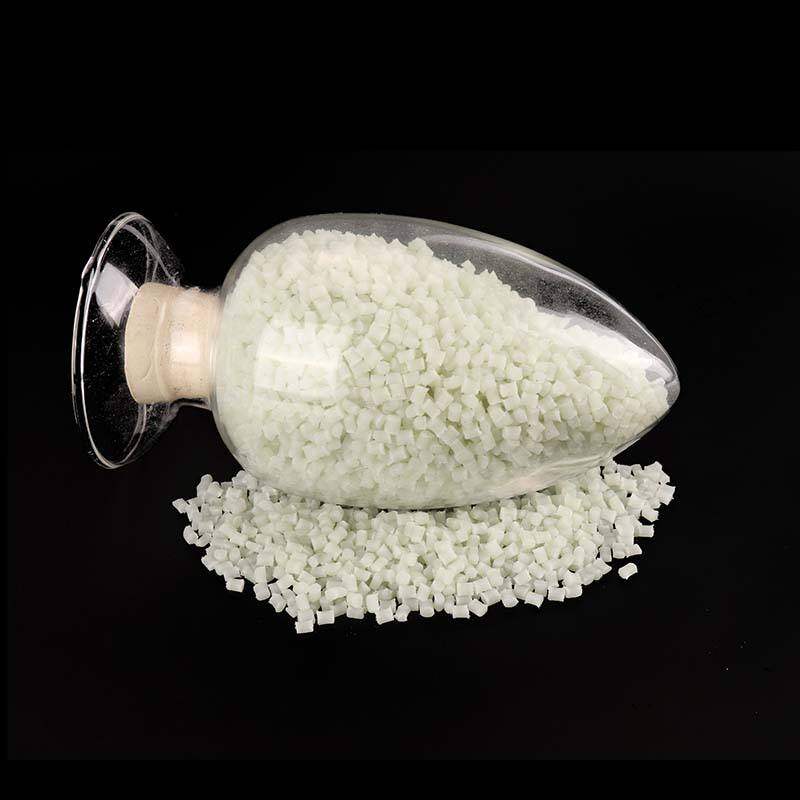

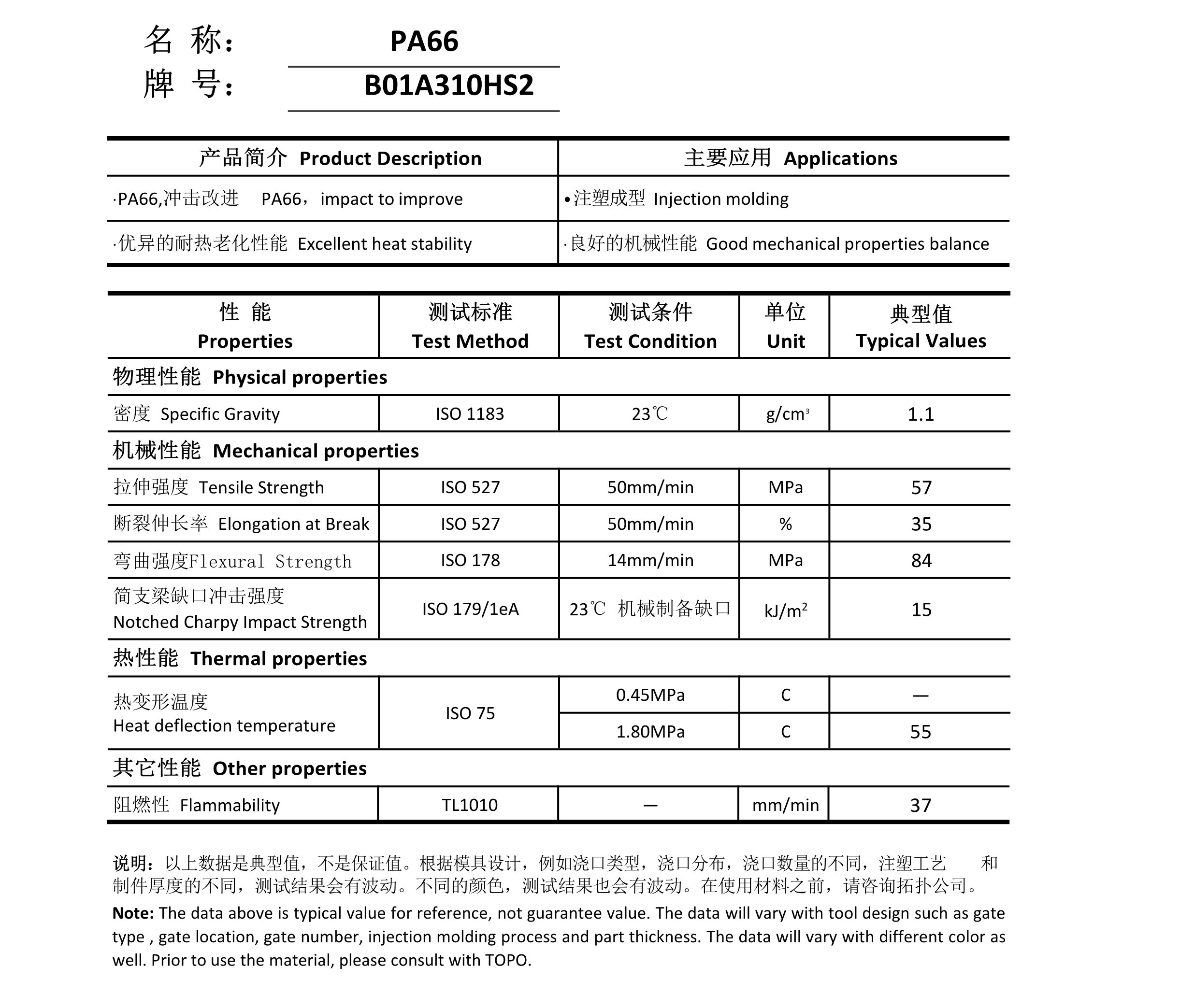

PA66 B01A310HS2

Suitable for plastic cable tie production

Impact improvement

(Custom materials available according to your Technical Data Sheet)

- Detalle del producto

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Another choice for cable tie material:

PA66 EP626F

Polyamide 66, commonly known as PA66, is a high-quality material widely used in various industries, particularly in the manufacturing of cable ties. This versatile material exhibits exceptional properties that make it an ideal choice for applications requiring strength, durability, and excellent mechanical performance.

PA66 is classified as a type of nylon resin, specifically nylon 66 resin. As a leading nylon 66 resin supplier, it possesses commendable strength and toughness, allowing it to withstand significant mechanical stress, making it an excellent choice for applications requiring resilience and durability.

Properties of PA66 Material:

-

Mechanical Strength: PA66 demonstrates high mechanical strength, ensuring its ability to withstand heavy loads and resist deformation. This property makes it suitable for applications where mechanical stress and impact resistance are crucial factors.

-

Thermal Stability: PA66 exhibits excellent thermal stability, enabling it to withstand a wide range of operating temperatures without significant degradation. This characteristic ensures its reliability under extreme conditions and increases its lifespan.

-

Chemical Resistance: PA66 is resistant to several chemicals, including oils, solvents, and alkalis, making it suitable for use in environments where exposure to chemicals is a concern. This property enhances the material's overall performance and longevity.

-

Electrical Insulation: PA66 possesses excellent electrical insulation properties, making it a reliable choice for applications in the electrical and electronics industry. Its high dielectric strength ensures safety and reliability in conducting electrical current.

-

Moisture Absorption: PA66 has moderate moisture absorption characteristics, allowing it to maintain its mechanical and electrical properties in humid environments. This property ensures its stability and performance even in areas with significant moisture.

In conclusion, PA66, also known as nylon 66 resin, is a remarkable material widely recognized for its exceptional properties. These include mechanical strength, thermal stability, chemical resistance, electrical insulation, and moisture absorption control. As a trusted supplier of nylon 66 resin, we provide high-quality materials that meet industry standards, ensuring reliable and durable solutions for various applications, particularly cable ties.

Q & A

1. What does 6 6 mean in nylon 6 6?

In nylon 6 6, the numbers refer to the chemical makeup of the polymer. Specifically, nylon 6 6 is a type of nylon that is formed from two different monomers: adipic acid and hexamethylenediamine. The "6 6" in nylon 6 6 represents the number of carbon atoms in each monomer.

2. History of nylon 6

Nylon 6 is a type of synthetic polymer that was first discovered and developed by a team of chemists at DuPont in the late 1930s. Wallace Carothers, a chemist at DuPont, is credited with the invention of nylon.

The development of nylon 6 began as part of a search for a synthetic alternative to silk, which was in high demand but expensive to produce. The research focused on creating a strong and durable fiber that could be used in various applications.

After years of experimentation, the chemists at DuPont successfully synthesized nylon 6 using a process called polymerization. They used caprolactam, a cyclic compound consisting of six carbon atoms, as the primary monomer. Through a series of chemical reactions, they were able to form long chains of repeating units, resulting in a strong and flexible polymer.

In 1938, DuPont introduced the first nylon product, known as nylon 6,6. It was initially used in toothbrush bristles, and soon after, it found applications in various industries such as textiles, automotive components, and packaging materials.

Nylon 6 revolutionized the textile industry by providing a lightweight and durable alternative to natural fibers like cotton and silk. It became a popular material for making stockings, earning it the nickname "nylons." During World War II, nylon 6 was primarily used for military applications such as parachutes, tents, and vehicle components.

The success of nylon 6 opened the door for further research and development of synthetic materials and polymers. Today, nylon 6 is still widely used in various industries due to its strength, durability, and versatility.

Download

-

PA66 B01A310HS2.pdf

Download PA66 B01A310HS2.pdf